Packaging plays a key role in how soap products are stored, presented, and transported in modern retail and online markets, and custom soap boxes design supports this process through accurate structure and material planning. Well-structured packaging helps protect soap bars from external factors while maintaining product integrity. Clear printing, balanced structure, and practical sizing contribute to better handling and organized presentation across different sales channels.

Soap packaging also supports brand communication by carrying product details, usage information, and visual identity. Thoughtful layout planning allows businesses to maintain consistency across product lines. Strong material selection and accurate dimensions help soaps remain intact during shipping and storage without unnecessary waste.

In the competitive soap industry, businesses rely on professional packaging partners such as soap boxes wholesale to manage bulk requirements with consistency and precision. Reliable packaging solutions allow soap makers to meet supply demands while maintaining packaging standards that align with market expectations.

custom soap boxes design

A well-planned custom soap boxes design focuses on structure, material quality, and print clarity. These elements work together to provide functional packaging that supports daily operations. Proper box dimensions prevent product movement, reducing handling issues during transport and display.

Material selection is another essential component of packaging design. Cardboard and paperboard materials provide strength while remaining lightweight. These materials allow clean folding, smooth printing, and accurate die-cutting, which helps maintain uniformity across production batches.

Print quality plays an equally important role. Clear typography, consistent color tones, and accurate alignment support product labeling needs. High-quality printing ensures ingredients, safety instructions, and branding elements remain readable throughout the product lifecycle. Balanced design layouts avoid clutter and improve visual organization.

Structural Planning for Soap Packaging

Structural planning begins with understanding soap size, shape, and weight. Rectangular bars, round soaps, and specialty shapes each require different box styles. Accurate measurements ensure that boxes fit securely without excess space.

Packaging structures such as tuck-end boxes, sleeve styles, and two-piece boxes offer flexibility for different soap categories. These structures allow efficient packing, easy opening, and secure closure. Selecting the right structure also supports faster assembly during large production runs.

Ventilation features can be included when required for moisture control. Small cut-outs or internal spacing help maintain product condition without affecting box strength. Structural features should always align with product handling needs and distribution methods.

Material Choices and Performance

Paperboard thickness directly impacts box performance. Lightweight boards support smaller soaps, while thicker boards suit heavier bars or multi-pack sets. Material consistency helps maintain uniform folding and stacking during storage.

Surface finishes also influence packaging usability. Matte coatings reduce glare and support readable text, while gloss coatings add visual sharpness. Finishing choices should align with printing methods and brand presentation goals.

Sustainable sourcing has become a standard practice in packaging production. Responsible material selection supports long-term business operations and compliance with industry standards without compromising functionality.

Printing Accuracy and Visual Balance

Printing accuracy ensures that every box meets quality expectations. Precise color matching helps maintain brand consistency across multiple product batches. Clean edges and sharp lines improve the overall appearance of packaging.

Visual balance keeps packaging easy to understand. Proper spacing between text, icons, and imagery prevents overcrowding. A clear hierarchy guides customers through product information without confusion.

Minimalistic layouts often work well for soap packaging. Simple designs communicate product value effectively while keeping production costs manageable. Consistent layouts across product lines also simplify inventory management.

Material Variations for Soap Packaging

Different soap products benefit from specific material variations based on their use and audience. Natural paper textures, coated surfaces, and reinforced boards allow brands to adapt packaging to various product categories.

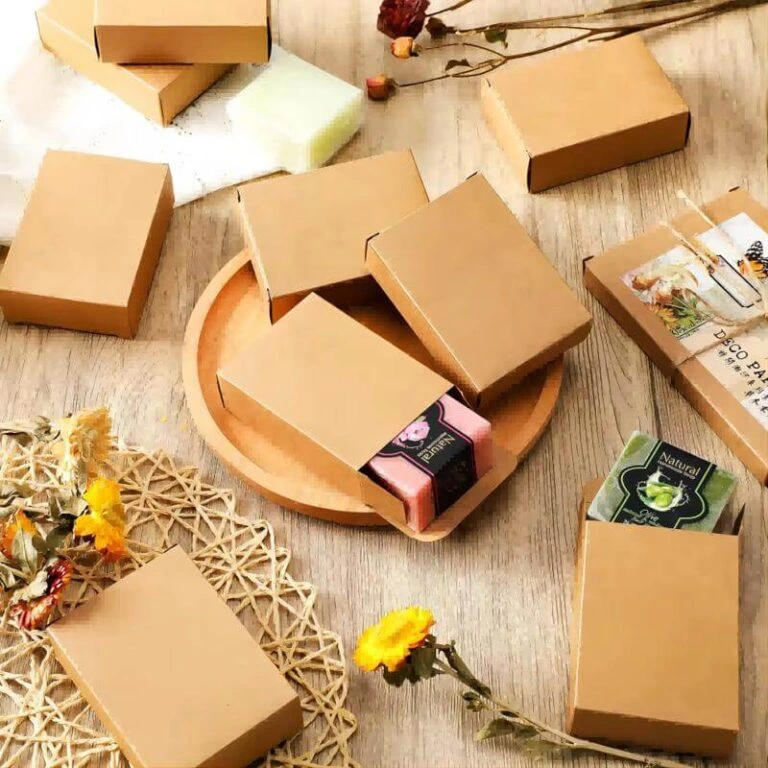

Packaging made with kraft soap boxes provides a clean and structured appearance suitable for many soap lines. This material supports straightforward printing and maintains box integrity during handling.

Premium paperboard options offer smoother surfaces and refined printing results. These materials are often selected for gift sets or limited-edition soap collections that require added presentation value.

Specialized Soap Packaging Categories

Handcrafted soaps often require packaging that reflects craftsmanship and attention to detail. Boxes designed for handmade soap boxes focus on precise sizing and gentle handling to protect unique shapes and finishes.

Bath products packaged as sets benefit from coordinated designs that maintain visual consistency. Using bath bomb gift boxes allows multiple items to be packed together securely while keeping individual products separated.

Specialized packaging solutions help businesses manage diverse product lines without compromising efficiency. Consistent structural standards simplify packing processes across categories.

Production Efficiency and Quality Control

Efficient production processes ensure timely delivery and consistent results. Standardized die lines and printing templates reduce setup time and material waste. Quality checks at each stage help identify alignment or cutting issues early.

Automation supports accuracy during large production runs. Machine-assisted folding and gluing maintain uniform box assembly. Manual inspection remains important for detecting minor defects before shipment.

Clear communication between designers, printers, and production teams improves workflow coordination. Detailed specifications help prevent errors and ensure final packaging meets expectations.

Storage, Shipping, and Handling Considerations

Packaging design must support storage efficiency. Flat-packed boxes save space before assembly, reducing warehouse requirements. Stackable designs improve organization during inventory management.

Shipping conditions influence packaging decisions. Boxes should maintain shape under standard transport conditions. Proper structural support prevents crushing or deformation during transit.

Clear labeling supports logistics and inventory tracking. Consistent placement of barcodes and product identifiers helps streamline order fulfillment processes.

Compliance and Information Accuracy

Soap packaging must comply with labeling regulations and industry standards. Ingredient lists, usage instructions, and safety notices must remain legible throughout the product lifecycle.

Accurate information placement helps prevent misinterpretation. Clear font sizes and contrast improve readability for customers and regulatory reviews.

Compliance-focused design protects businesses from potential issues while maintaining customer trust. Packaging that meets standards supports smooth market distribution.

Long-Term Packaging Strategy

A long-term packaging strategy balances cost management, visual consistency, and operational efficiency. Planning ahead allows businesses to adapt packaging designs as product lines expand.

Regular reviews of packaging performance help identify areas for improvement. Adjustments to materials, structure, or layout can improve handling without redesigning entire systems.

By focusing on thoughtful planning and precise execution, structured soap packaging solutions support reliable results that align with business goals and customer expectations.

FAQs

Q1: What is a custom soap boxes design?

A1: In the USA, a custom soap boxes design refers to packaging created specifically for soap bars or sets that meets American retail standards. It considers size, shape, material, and printing preferences common in the US market, ensuring protection, handling efficiency, and attractive display for consumers.

Q2: Why are kraft soap boxes important for soap packaging in the USA?

A2: Kraft soap boxes are popular in the USA because they are sturdy, affordable, and easy to print with high-quality designs. They are widely used for retail and online sales, providing a clean and professional look while protecting soaps during shipping across states.

Q3: How do handmade soap boxes differ from regular soap boxes in the USA?

A3: Handmade soap boxes in the US are designed to protect artisanal or small-batch soaps that are often sold at farmers markets, craft stores, and online platforms. They emphasize precise sizing, gentle handling, and appealing designs that meet US consumer expectations for handcrafted products.

Q4: What are bathbomb gift boxes used for in the US?

A4: In the USA, bathbomb gift boxes are used for packaging sets of bath products sold in retail stores, online marketplaces, or as gifts. They keep multiple bath items separated, secure, and visually appealing, which is especially important for seasonal sales or subscription boxes.

Q5: What materials are commonly used for soap box packaging in the USA?

A5: In the US, cardboard and paperboard are the most common materials. They are cost-effective, lightweight for domestic shipping, easy to print on, and comply with US recycling standards, making them ideal for eco-conscious brands.

Q6: How does custom packaging help soap brands in the USA?

A6: Custom packaging helps US soap brands stand out in a competitive market. It protects products during shipping, supports brand identity for retail shelves or online sales, and provides a professional look that appeals to American consumers.

Q7: Can soap boxes be designed for different shapes and sizes in the USA?

A7: Yes. US brands often sell soaps in rectangular, circular, or unique specialty shapes. Custom soap boxes design ensures each shape fits securely, meets retail display standards, and protects products during nationwide shipping.

Q8: How can US businesses maintain consistent soap packaging quality?

A8: US businesses maintain quality by using reliable American packaging suppliers, standardized die lines, consistent material selection, precise printing, and quality control checks during each production run to meet customer expectations and regulatory standards.