Ordering soap boxes wholesale might seem straightforward—until it isn’t. In the U.S. market, packaging is no longer just about protecting the product; it’s a sales tool, a compliance requirement, and a brand signal all rolled into one. After working closely with American soap brands, startups, and large-scale manufacturers, one thing is clear: the businesses that plan their packaging strategy upfront save money, avoid delays, and scale faster.

This pillar guide breaks down everything you need to know before ordering soap boxes wholesale in the USA, so you can make informed decisions, avoid costly mistakes, and invest in packaging that actually works for your brand.

Understanding the Role of Soap Packaging in the U.S. Market

In the United States, consumers associate packaging quality directly with product value. A premium soap in flimsy packaging struggles to earn trust, while a well-packaged bar can justify a higher price point instantly.

Retailers, subscription boxes, farmers’ markets, and eCommerce platforms all have different expectations. Wholesale soap packaging must balance durability, shelf appeal, compliance, and cost-efficiency. That’s why smart brands think beyond “just a box” and treat packaging as part of their marketing strategy.

Defining Your Wholesale Packaging Goals Before You Order

Before contacting a supplier, clarity is everything. Wholesale orders lock in decisions that can affect your margins for months or even years.

Start by identifying your primary use case. Are you selling individual bars, curated gift sets, or seasonal collections? Packaging for boutique retail shelves differs from packaging designed for shipping-heavy eCommerce fulfillment. Your answers shape material choice, structure, and print approach.

Brands ordering soap boxes wholesale without defined goals often overpay for features they don’t need—or underinvest in elements that matter most to customers.

Choosing the Right Box Style for Your Soap Products

Soap packaging isn’t one-size-fits-all. Bar thickness, curing method, fragrance strength, and branding style all influence box structure.

For example, minimalist brands often prefer open or breathable designs that let the product speak for itself, while luxury brands lean toward fully enclosed, rigid options. Specialty styles like soap boxes with window are popular in U.S. retail because they let customers see texture and color without opening the package.

The key is matching form to function. A visually striking box that doesn’t protect the soap during transit will cost you in returns and damaged inventory.

Material Selection: More Than Just Cardboard

Material choice impacts cost, sustainability perception, and structural integrity. In the USA, eco-conscious packaging isn’t a trend—it’s an expectation.

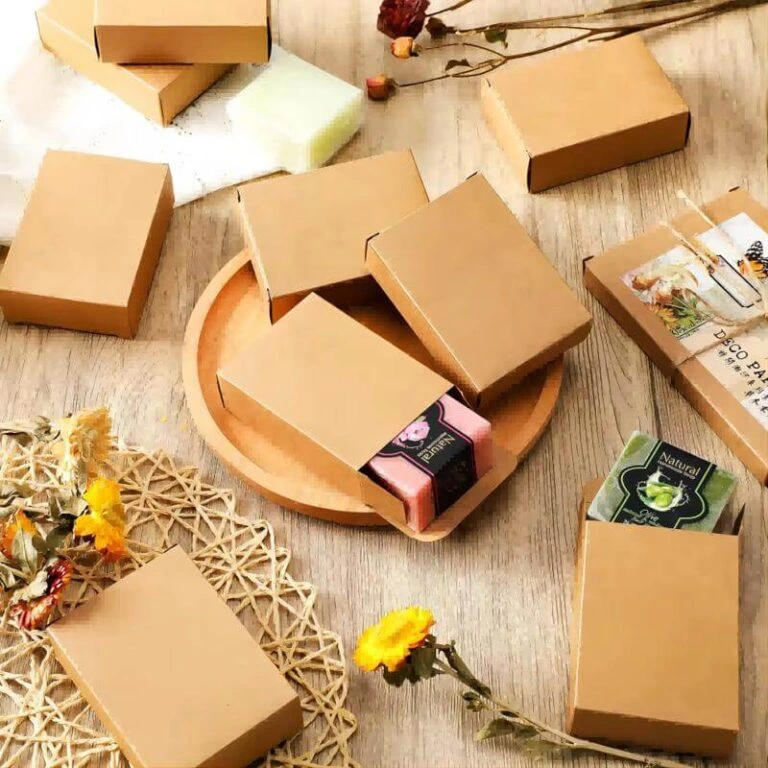

Many brands choose kraft soap boxes for their recyclable nature and organic aesthetic, especially for handmade or plant-based soaps. Others prefer white SBS paperboard for high-end printing and bold color accuracy.

If you’re shipping nationwide, durability matters just as much as appearance. Thin stock may lower upfront costs but often leads to crushed boxes during transit, especially when ordering soap boxes bulk quantities.

Customization vs. Standard Wholesale Boxes

One of the biggest decisions is whether to go fully custom or semi-custom. Custom soap boxes wholesale allow you to control dimensions, branding, messaging, and finish—but they require longer lead times and higher minimums.

Standard wholesale boxes offer speed and affordability but limit brand differentiation. For U.S. brands competing in crowded categories, custom printing often pays for itself by improving shelf visibility and repeat purchases.

If branding is a growth priority, custom printed soap boxes wholesale are a strategic investment rather than a cost.

Print Quality and Branding Consistency

Inconsistent printing is one of the most common complaints in wholesale packaging. Color shifts, blurry logos, or misaligned artwork can weaken brand credibility instantly.

U.S. consumers notice details. Crisp typography, accurate color matching, and high-resolution imagery signal professionalism. Before placing a large order, always review physical samples—not just digital proofs.

High-quality printing is especially critical when packaging premium products or selling through curated retail channels.

Compliance and Labeling Requirements in the USA

Soap packaging in the U.S. must align with FDA guidelines, especially if the product makes cosmetic or therapeutic claims. Packaging must allow space for ingredient lists, net weight, manufacturer information, and disclaimers when required.

Designing boxes without considering compliance can lead to relabeling costs or distribution delays. This is where experience matters—working with a supplier familiar with soap boxes wholesale USA standards reduces risk significantly.

Sustainability Expectations and Consumer Trust

American consumers increasingly expect brands to demonstrate environmental responsibility. Packaging is often the first place they look.

Using recyclable, biodegradable, or responsibly sourced materials builds trust and supports brand storytelling. However, sustainability claims must be genuine. Overstating eco-benefits on packaging can backfire and damage credibility.

Sustainable packaging isn’t just good ethics—it’s good business in the U.S. market.

Minimum Order Quantities and Scalability

Wholesale pricing improves with volume, but ordering too much too soon can strain cash flow and storage space. This is a common challenge for growing brands.

When evaluating wholesale soap boxes, look for suppliers that offer scalable MOQs. Being able to reorder the same design in higher quantities later ensures consistency without overcommitting upfront.

Scalability is especially important if you plan seasonal launches or frequent design updates.

Lead Times, Production Speed, and Supply Chain Reality

In the U.S., timing matters. Missed launch dates, holiday windows, or retail onboarding deadlines can cost real revenue.

Custom packaging typically requires longer production cycles, especially during peak seasons. Domestic production often offers faster turnaround, while overseas manufacturing may reduce unit cost but increase risk and delays.

Understanding lead times upfront helps you align packaging orders with inventory planning.

Shipping, Storage, and Fulfillment Considerations

Packaging doesn’t stop at production—it must survive storage and shipping. Flat-packed boxes save space and reduce freight costs, but they require assembly labor.

For eCommerce brands, box durability directly affects customer experience. Crushed or damaged packaging undermines even the best soap formulations.

Design choices should account for how your boxes move through warehouses, fulfillment centers, and delivery networks.

Cost Breakdown: What You’re Really Paying For

Wholesale pricing reflects more than box quantity. Material quality, print method, finishing options, tooling, and freight all contribute to total cost.

Transparent suppliers explain where your money goes. This clarity helps you compare quotes accurately and avoid surprises after production begins.

The cheapest option isn’t always the most cost-effective long term—especially if it compromises brand perception or product protection.

Matching Packaging to Product Lines and Variations

If your brand offers multiple products—like soaps, bath products, and gift sets—packaging consistency matters. Using cohesive design systems across bath bomb boxes, soap packaging, and bundled offerings strengthens brand recognition.

Packaging should evolve logically across your catalog while maintaining a unified look. This is especially important for brands expanding into curated collections or subscription models.

Specialty Packaging for Gifting and Premium Sales

Gift-ready packaging plays a major role in U.S. consumer purchasing decisions, especially during holidays. A well-designed soap gift box elevates perceived value without changing the product itself.

Premium packaging supports higher price points and encourages impulse buys, both online and in-store. When gifting is part of your sales strategy, packaging deserves special attention.

Structural Precision for Individual Soap Bars

Fit matters. A poorly sized soap bar box can cause movement, scuffing, or breakage. Custom dimensions ensure the soap stays secure while maintaining a polished presentation.

Precision also reduces material waste and shipping inefficiencies. Over time, these small improvements compound into meaningful cost savings.

Supporting Artisanal and Handmade Brands

Handcrafted soap brands often need packaging that reflects authenticity and craftsmanship. Custom handmade soap boxes allow these brands to tell their story while maintaining professional polish.

In the U.S. artisan market, packaging bridges the gap between small-batch production and retail-ready presentation. Done right, it builds trust without losing the handmade feel.

Why Supplier Expertise Makes a Difference

Not all packaging suppliers understand the nuances of the U.S. soap market. Experience matters—from material sourcing to compliance awareness and print accuracy.

A knowledgeable partner like Soap Boxes Wholesale doesn’t just manufacture boxes; they guide brands through decisions that affect cost, branding, and scalability. That guidance is often the difference between smooth growth and constant packaging headaches.

Final Thoughts: Ordering Wholesale with Confidence

Ordering soap boxes wholesale in the USA is a strategic decision, not a transactional one. The right packaging protects your product, communicates your brand, meets regulatory standards, and supports long-term growth.

By understanding materials, customization, compliance, and logistics before placing an order, you position your brand for success in a competitive market. With the right planning—and the right partner—your packaging becomes an asset, not an afterthought.

Soap Boxes Wholesale brings firsthand industry experience, U.S. market insight, and scalable solutions to help brands package smarter and grow stronger. When you’re ready to order with confidence, expertise makes all the difference.